Description

The SD series diesel engine features a high reliability, good fuel economy and fast transient load response. It is an outstanding representative of recently designed and leading technical indexes among domestic proven engines. With three optional engines of 5.3, 9.3 and 8.8L, the applicable power ranges from 132 to 375 Ps, making it the preferred power for medium sized passenger buses and city busses.

The prototype of SD series is jointly designed with the Austrian company AVL to adapt to Chinese oil quality and user habits. In 2005, SMAN cooperated with the American SwRI to carry out reinforcing design and 4-valve upgrade following North American heavy-duty diesel engine standards. Meeting Tier IV, V emission standards, this series engine has been selling well for 20 years, with currently more than 1 million sets in circulation.

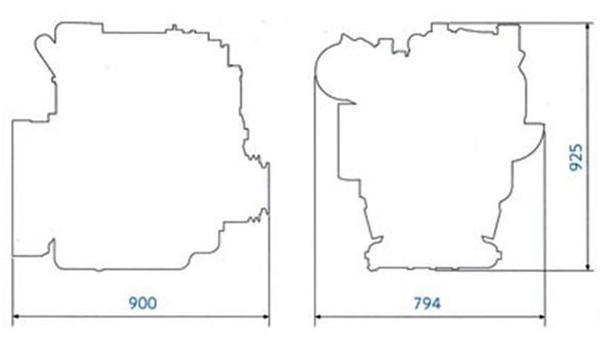

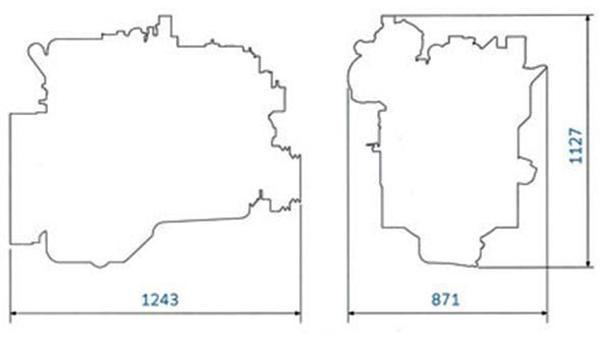

Outline dimensional drawing

Technical parameters

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Emissions Level | |||

| kW | ps | r/min | N.m | r/min | |||||

| 5SDK | 5SDK180 | 5.3 | TA | 132 | 180 | 2300 | 660 | 1400 | China IV |

| 5SDK | 5SDK200 | 5.3 | TA | 147 | 200 | 2300 | 730 | 1400 | China IV |

| 8SDK | 8SDK230 | 8.3 | TA | 170 | 230 | 2200 | 900 | 1400 | China IV |

| 8SDK | 8SDK240 | 8.3 | TA | 177 | 241 | 2200 | 960 | 1400 | China IV |

| 8SDK | 8SDK250 | 8.3 | TA | 184 | 250 | 2200 | 1000 | 1400 | China IV |

| 8SDK | 8SDK260 | 8.3 | TA | 192 | 260 | 2200 | 1100 | 1400 | China IV |

| 8SDK | 8SDK280 | 8.3 | TA | 206 | 280 | 2200 | 1160 | 1400 | China IV |

| 9SDK | 9SDK280 | 8.8 | TA | 206 | 280 | 2200 | 1160 | 1400 | China IV |

| 9SDK | 9SDK310 | 8.8 | TA | 228 | 310 | 2200 | 1250 | 1400 | China IV |

| 9SDF | 9SDF240 | 8.8 | TA | 177 | 240 | 2200 | 970 | 1400 | China IV, China V |

| 9SDF | 9SDF260 | 8.8 | TA | 192 | 260 | 2200 | 1100 | 1400 | China IV, China V |

| 9SDF | 9SDF280 | 8.8 | TA | 206 | 280 | 2200 | 1160 | 1400 | China IV, China V |

| 9SDF | 9SDF300 | 8.8 | TA | 221 | 300 | 2200 | 1250 | 1400 | China IV, China V |

| 9SDF | 9SDF320 | 8.8 | TA | 235 | 320 | 2200 | 1350 | 1400 | China IV, China V |

| 9SDF | 9SDF340 | 8.8 | TA | 251 | 340 | 2200 | 1450 | 1400 | China IV, China V |

| Natural Gas Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Emissions Level | |||

| kW | ps | r/min | N.m | r/min | |||||

| 5SDT | 5SDT180 | 5.3 | TA | 132 | 180 | 2300 | 650 | 1500 | China V |

| 8SDT | 8SDT230 | 8.3 | TA | 170 | 230 | 2000 | 830 | 1300 | China V |

| 8SDT | 8SDT250 | 8.3 | TA | 184 | 250 | 2000 | 920 | 1300 | China V |

| 9SDT | 9SDT280 | 8.8 | TA | 206 | 280 | 2000 | 1120 | 1300 | China V |

| 9SDT | 9SDT300 | 8.8 | TA | 221 | 300 | 2000 | 1150 | 1300 | China V |

| 9SDT | 9SDT320 | 8.8 | TA | 235 | 320 | 2000 | 1200 | 1300 | China V |

Features

| SD Series | Technical advantages and features | Customer value |

| Fuel system | It adopts Japan Denso third generation of electronic control system with a maximum injection pressure of 1800bar. The DLC coated fuel injector of Denso patented technology can reduce the corrosion and wear of oil nozzle. Multiple injection can be realized in sequential working conditions to ensure uniform atomization and full combustion. This engine meets Tier IV, V emission standards. | The oil consumption is reduced by 10-15%, with a long service life. |

| Gas system | It uses a single point injection gas supply mode and two control strategies: lean burning and mixed burning (lean burning + equivalent burning). The controller (ECU), sensor, electronic throttle, sparking coil, spark plug and other key components are all from internationally known brands, and meet Chinese V emission standards. | This system is advanced and reliable. |

| Aspiration method | With optional 2-valve and 4-valve products, an optimized combustion chamber and swirl ratio airway, the turbocharger is selected based on various working conditions, power and torque requirements. This achieves a higher air intake efficiency and improves the combustion efficiency. With its high power density and fast transient load, the maximum torque reserve is up to 40%. | With a low fuel consumption, the operation cost is low. It has a fast transient load response, strong power and outstanding adaptability to working conditions. |

| Design features | In cooperation with AVL and SwRI, this product meets North American heavy-duty diesel engine standards. With a high strength cylinder head and engine block, 4-valve structure and 180bar peak pressure, all the parts are designed as 295kW. Using an integral design, the parts are 20% less than the regular diesel engines. Compared to same power engines available on the market, it has a simpler and smaller structure. The 217Ps in-cylinder brake power is an option offered to meet better auxiliary braking functions. |

This engine has an excellent reliability and low downtimes. The overall arrangement is flexible. A high power in-cylinder brake results in a high driving safety. |

| Reliability features | Designed following 295kW heavy-duty diesel engine designs, it has a high reliability margin. With advanced machining and assembly lines, it is controlled by an MES system. By referencing the SPS system guarantee in German Volkswagen manufacturing standards, the product has a better consistency. With advanced and reliable international first-class accessories, this engine has been selling well for 10 years as the preferred power of commercial vehicles. | It is advanced, mainstream, reliable and reassuring. |

| Matching adaptabilit | With an optional displacement of 8.3L and 8.8L and optional engine of diesel and natural gas, the power ranges from 105kW to 275kW. Electronically controlled common rail and natural gas systems are developed and manufactured on one platform. The electronic controlled engine supports GPS, cruising and other functions. Without an auxiliary air intake heating device, the cold starting temperature is -15℃. According to the assembly configuration and actual operating conditions, the engine and assembly are conducted for matching optimization and customization. Various configurations for the flywheel, flywheel house, engine, air compressor, steering pump and other peripheral parts are provided to choose from. There are also different structures and types to choose from for the PT0 and oil pan. | This engine has a wide application range and good environmental adaptability. It has an optimized power performance and economy. |