Description

The MK6L series diesel engine for commercial water pump was designed as part of a joint operation between SMAN and Austria AVL. We produced a reinforced design and 4-valve upgrade in 2005 when we cooperate with The Southwest Research Institute (SwRI). All parts are designed and checked according to 480kW outputs and it has an applicable power range of 130-310kW with a large reliability margin. The engine provides good fuel economy and this is the most technically advanced engine in Malaysia. It has been selling well for over 20 years, with production of more than 1 million sets. This is the idle matching power for 130-350 kW water pump.

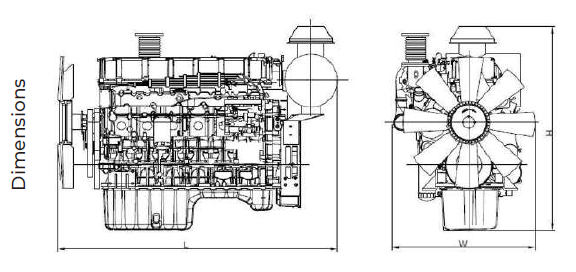

Outline dimensional drawing

Specification

|

Engine Model |

MK6L160H |

MK6L173H |

MK6L207H |

MK6L234H |

MK6L253H |

|

Air intake mode |

Turbo & Inter-Cooled |

||||

|

Combustion mode |

Direct injection |

||||

|

Cylinder number |

6 |

6 |

6 |

6 |

6 |

|

Bore x Stroke (mm) |

105 x 130 |

105 x 1 35 |

105 x 135 |

105x135 |

113x130 |

|

Output volume (L) |

6.75 |

6.75 |

7.01 |

7.69 |

7.82 |

|

Compression ratio |

17:1 |

16:1 |

16:1 |

16.1 |

15:1 |

|

Main Power (kW) |

120 |

130 |

155 |

175 |

190 |

|

Speed (r/min) |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Maximum no load governed speed (r/min) |

≤ 1890 |

≤ 1890 |

≤ 1890 |

≤ 1890 |

≤ 1890 |

|

Minimum no load stable speed (r/min) |

≤ 650 |

≤ 650 |

≤ 650 |

≤ 650 |

≤ 650 |

|

Fuel consumption (g/kw.h) |

218 |

224 |

224 |

224 |

210 |

|

12h Fuel flowmeter (L/h) |

31 |

34 |

40 |

44 |

46 |

|

Cooling system |

Forced Water Cooling |

||||

|

Lubricating system |

Pressure spattet Compound |

||||

|

Start model |

Electric start: 24V / 130Ah (Dynamo: 28V/12.5A) |

||||

|

Net Weight (kg) |

570 |

630 |

630 |

630 |

670 |

|

Cylinder working sequence |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

|

Exhaust temperature (oC) |

≤ 600 |

≤ 600 |

≤ 600 |

≤ 600 |

≤ 550 |

|

Intake pipe diameter (mm) |

76 |

76 |

76 |

76 |

100 |

|

Total oil capacity (L) |

16 |

16 |

16 |

16 |

18 |

|

Maximum oil temperature (oC) |

105 |

105 |

105 |

105 |

105 |

|

Oil consumption (g/kw.h) |

≤ 1.63 |

≤ 1.63 |

≤ 1.63 |

≤ 1.68 |

≤ 1.63 |

|

Total cooling water capacity (L) |

23 |

25 |

25 |

25 |

28 |

|

Engine Model |

MK6L267H |

MK6L294H |

MK6L294H |

MK6L374H |

MK6L411H |

|

Air intake mode |

Turbo & Inter-Cooled |

Turbocharged |

|||

|

Combustion mode |

Direct injection |

||||

|

Cylinder number |

6 |

6 |

6 |

6 |

6 |

|

Bore x Stroke (mm) |

126 x 130 |

126 x 130 |

126 x 130 |

126 x 130 |

126 x 135 |

|

Output volume (L) |

7.82 |

8.5 |

8.82 |

9.73 |

10.9 |

|

Compression ratio |

15:1 |

16:1 |

15:1 |

17:1 |

17:1 |

|

Main Power (kW) |

200 |

220 |

250 |

280 |

308 |

|

Speed (r/min) |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Maximum no load governed speed (r/min) |

≤ 1890 |

≤ 1890 |

≤ 1890 |

≤ 1890 |

≤ 1890 |

|

Minimum no load stable speed (r/min) |

≤ 650 |

≤ 650 |

≤ 650 |

≤ 650 |

≤ 650 |

|

Fuel consumption (g/kw.h) |

215 |

210 |

210 |

215 |

215 |

|

12h Fuel flowmeter (L/h) |

56 |

59 |

59.3 |

63.5 |

64 |

|

Cooling system |

Forced Water Cooling |

||||

|

Lubricating system |

Pressure spattet Compound |

||||

|

Start model |

Electric start: 24V / 130Ah (Dynamo: 28V/12.5A) |

||||

|

Net Weight (kg) |

850 |

850 |

850 |

1090 |

1150 |

|

Cylinder working sequence |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

1-5-3-6-2-4 |

|

Exhaust temperature (oC) |

≤ 55 0 |

≤ 550 |

≤ 550 |

≤ 600 |

≤ 600 |

|

Intake pipe diameter (mm) |

100 |

100 |

100 |

100 |

100 |

|

Total oil capacity (L) |

18 |

19 |

19 |

27 |

27 |

|

Maximum oil temperature (oC) |

105 |

105 |

105 |

105 |

105 |

|

Oil consumption (g/kw.h) |

≤ 1.63 |

≤ 1.68 |

≤ 1.68 |

≤ 1.68 |

≤ 1.68 |

|

Total cooling water capacity (L) |

28 |

28 |

28 |

39 |

39 |

Scope of Supply:

Radiator, 24V starter motor, Engine shaft / Control panel: Customer’s request.

These engines have improved performance and combustion efficiency. The characteristics such as high torque and heavy duty construction makes these engines a right choice for fire fighting applications. Engines series comprises of 6 cylinder 4 stroke compression ignition type engines. These engines are subjected to rigorous per formance tests prior to the dispatch to ensure that the performance ratings are achieved as required by the design specifications.